MAXX capsule filling machine

CHARACTERISTICS

Cost effectiveness and great output

Versatile and robust, the semi-automatic capsule filling MAXX allows the customization of all the encapsulation steps without losing productivity: from the capsule insertion speed to the strength and time of capsule closing, everything can be adjusted according to the characteristics of each product to be encapsulated.

With output¹ from 10,000 to 25,000 capsules/hour. MAXX performs the three main operations involved in encapsulation

- Placement of the capsules in the disk set;

- Feeding and compacting the powder inside the capsules

- Closing / locking and removal of the capsules.

Disk sets have variable capacity, according to the size of the capsule, which allows the maximum use of the productivity of each part. The capsule feeding unit has a frequency variator that allows to change the capsule insertion speed according to each need.

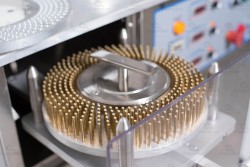

The powder feeding unit allows controlling the speed of the plate, the number of turns, and the level of powder compaction inside the capsule. The capsule closing unit, called the porcupine, works with compressed air²,³ and allows the regulation of the pressure to close the shells and the activation time of the piston, which minimizes the occurrence of crushed or damaged capsules. Its operation is silent and harmonious, without losing the robustness of the equipment.

Versatile and robust, the semi-automatic capsule filling MAXX allows the customization of all the encapsulation steps without losing productivity: from the capsule insertion speed to the strength and time of capsule closing, everything can be adjusted according to the characteristics of each product to be encapsulated.

With output¹ from 10,000 to 25,000 capsules/hour. MAXX performs the three main operations involved in encapsulation

- Placement of the capsules in the disk set;

- Feeding and compacting the powder inside the capsules

- Closing / locking and removal of the capsules.

Disk sets have variable capacity, according to the size of the capsule, which allows the maximum use of the productivity of each part. The capsule feeding unit has a frequency variator that allows to change the capsule insertion speed according to each need.

The powder feeding unit allows controlling the speed of the plate, the number of turns, and the level of powder compaction inside the capsule. The capsule closing unit, called the porcupine, works with compressed air²,³ and allows the regulation of the pressure to close the shells and the activation time of the piston, which minimizes the occurrence of crushed or damaged capsules. Its operation is silent and harmonious, without losing the robustness of the equipment.

TECHNICAL SPECIFICATIONS

The capsule filling process using the MAXX semi-automatic machine can be divided into 3 steps:

Step 1 – Capsule feeding

The equipment aligns and directs the capsules into the disk set, while a high-efficiency vacuum system opens the shells. The capsule feed unit is automatically shut off once the disc set is completed.

Step 2 – Powder filling

In this station, the capsules are filled with powder automatically. The powder feeding unit has plate speed control, thread height control, stirrer speed control and turning control. After filling the shells with powder, the disk set is assembled (thin disk placed over the thick disk) and should be placed onto the closing station.

Step 3 – Closing and locking the capsules

At the closing station a pneumatic system²,³ closes and locks the shells. The system allows to select of the pressure that the capsules are closed and also the piston activation time (which facilitates the work in case of very adherent powders), these elements minimize the occurrence of waste due to capsules that eventually dent during the closing and locking.

Production: 10,000 to 25,000 capsules/hour*

Dimensions: 97 x 58 x 182 cm (length x width x height)

Weight: 280 kg

Motors:

Capsule feeding: 0.25 HP (three-phase)

Powder feeding: 0.5 HP (three-phase)

Disk plate: 0.25 HP (three-phase)

Vacuum pump: 1 HP (three-phase)

Voltage: 220 or 380 volts (three-phase) (this is NOT a multi voltage equipment) (different equipment according to the selected voltage)

Compressed air pressure2,3: 6 to 8 bar

Approximate consumption: 1,7 kWh

Step 1 – Capsule feeding

The equipment aligns and directs the capsules into the disk set, while a high-efficiency vacuum system opens the shells. The capsule feed unit is automatically shut off once the disc set is completed.

Step 2 – Powder filling

In this station, the capsules are filled with powder automatically. The powder feeding unit has plate speed control, thread height control, stirrer speed control and turning control. After filling the shells with powder, the disk set is assembled (thin disk placed over the thick disk) and should be placed onto the closing station.

Step 3 – Closing and locking the capsules

At the closing station a pneumatic system²,³ closes and locks the shells. The system allows to select of the pressure that the capsules are closed and also the piston activation time (which facilitates the work in case of very adherent powders), these elements minimize the occurrence of waste due to capsules that eventually dent during the closing and locking.

Production: 10,000 to 25,000 capsules/hour*

Dimensions: 97 x 58 x 182 cm (length x width x height)

Weight: 280 kg

Motors:

Capsule feeding: 0.25 HP (three-phase)

Powder feeding: 0.5 HP (three-phase)

Disk plate: 0.25 HP (three-phase)

Vacuum pump: 1 HP (three-phase)

Voltage: 220 or 380 volts (three-phase) (this is NOT a multi voltage equipment) (different equipment according to the selected voltage)

Compressed air pressure2,3: 6 to 8 bar

Approximate consumption: 1,7 kWh

| Capsule size | Approximate output/hour |

| 000 | ≈ 10.000 a 11.000 |

| 00 AL | ≈ 16.000 a 19.000 |

| 00 | ≈ 16.000 a 19.000 |

| 0 AL | ≈ 20.000 a 23.000 |

| 0 | ≈ 20.000 a 23.000 |

| 1 | ≈ 23.000 a 26.000 |

| 2 | ≈ 23.000 a 26.000 |

| 3 | ≈ 25.000 a 28.000 |

| 4 | ≈ 25.000 a 28.000 |

- 1Production output varies according to capsule quality, powder characteristics, humidity and temperature conditions of the environment, and operator ability. 2Air compressor not included. 3We suggest at least a 50L compressed air storage tank.